Casting and molding machines frame the spine of advanced mechanical fabricating, encouraging the generation of diverse components and items employing an assortment of materials. This outline dives into fundamental sorts such as infusion molding, known for its exactness in plastic portion generation, and kick-the-bucket casting, which exceeds expectations in making strong metal components. These casting and molding machines play basic parts in businesses like car, bundling, aviation, assembly rigid quality, and execution prerequisites.

Outline of Mechanical Casting and Molding Machines

Key machines such as infusion molding and pass-on casting are significant for productive generation in car, bundling, and aviation businesses. They guarantee the exact fabricating of components basic to these sectors’ execution and unwavering quality.

Infusion Molding Machines

Infusion molding machines are urgent in mechanical fabricating for their capacity to deliver complicated plastic components with high accuracy and productivity. These machines work by infusing liquid fabric into a form beneath strong weight, encouraged by an infusion unit, a clamping unit to secure the form, and a water-powered framework for control. Broadly utilized in the car, gadgets, and buyer merchandise businesses, infusion molding exceeds expectations in the high-volume generation of parts requiring tight resistances and complex geometries.

Expulsion Molding Machines

Expulsion molding machines are basic for making persistent shapes such as tubes, channels, and sheets from different materials like plastics and metals. This handle involves pushing liquid fabric through a molded kick of the bucket employing a screw or slam, which shapes the fabric because it passes through. A cooling framework sets the item after shaping. Perfect for businesses like development, bundling, and car fabricating, expulsion molding empowers the generation of reliable cross-sectional profiles in expansive amounts productively.

Compression Molding Machines

Compression molding machines utilize warmth and weight to shape materials such as elastic, composites, and thermosetting plastics into craved shapes. These machines include a form that shapes the fabric beneath weight from a platen, with warming components guaranteeing appropriate curing or dissolving of the fabric. Compression molding is favored for its capacity to deliver complex shapes with a fabulous surface wrap-up and is commonly utilized in aviation, electrical, and car businesses for low-volume generation runs.

Pass-on Casting Machines

Pass-on casting machines are basic for creating nitty gritty and solid metal parts with tall dimensional precision. This preparation includes infusing liquid metal, regularly aluminum or zinc, into a steel form at tall weights. Die-casting machines incorporate an infusion framework for conveying the liquid metal, a kick-the bucket that shapes the ultimate portion, and a cooling framework to set the metal rapidly. Broadly utilized in car, aviation, and customer hardware businesses, kick the bucket casting permits for the productive generation of complex metal components.

Vacuum Molding Machines

Vacuum molding machines are utilized to shape plastic sheets by warming them until malleable and after that shaping them over molds utilizing vacuum weight. These machines incorporate warming components to relax the plastic, molds that characterize the shape of the ultimate item, and vacuum frameworks to draw the plastic firmly against the shape surface. Vacuum molding is favored for its capacity to form nitty gritty and lightweight items such as bundling, shopper merchandise, and car components with reliable quality.

Rotational Molding Machines

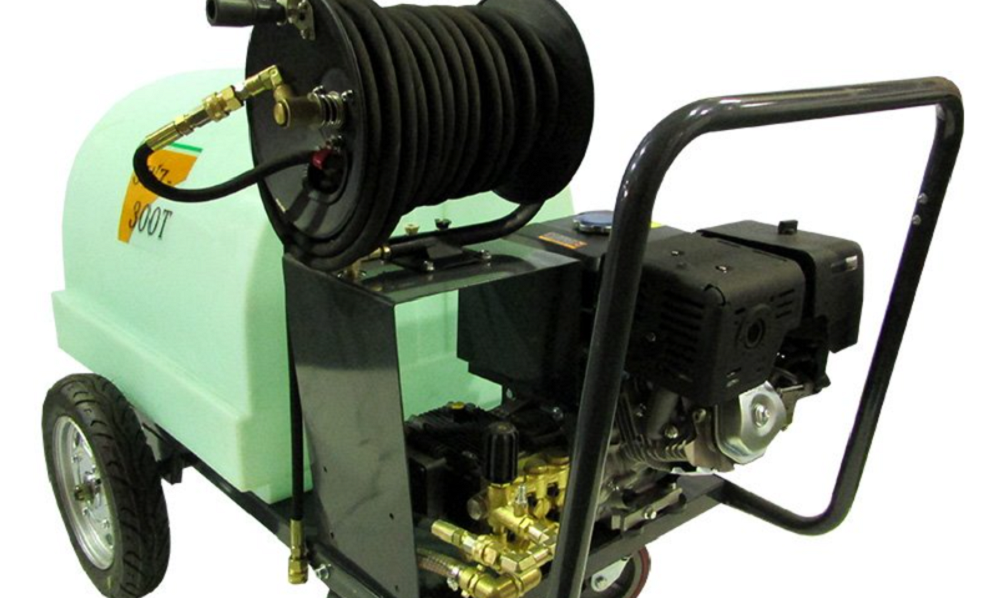

Rotational molding machines are utilized to make hollow things such as capacity tanks and play area hardware employing a rotational preparation. This strategy dissolves and coats the inward surface of a form with polymer fabric, which is at that point pivoted in a broiler to equally disseminate the fabric and shape the specified shape. Once cooled, the molded portion holds a consistent development. This method is profitable for creating huge, complex, and empty items with uniform divider thickness and strength, commonly utilized in car and recreational businesses.

Blow Molding Machines

Blow molding machines make empty items such as bottles and holders by blowing up liquid fabric interior a form depression utilizing discuss pressure. These machines regularly incorporate an extruder for softening and forming the polymer, molds that characterize the shape of the ultimate item, and blow pins to blow up the fabric’s interior shape. Blow molding is proficient for creating lightweight and strong items in tall volumes, making it a staple in businesses like bundling, car, and therapeutic divisions.

Thermoforming Machines

Thermoforming machines shape thermoplastic sheets into particular shapes using heat, vacuum, pressure, or mechanical force. These machines warm the thermoplastic sheet until it is pliable, and at that point frame it over a form to form the required shape. Cooling frameworks cement the molded portion for evacuation. Thermoforming is flexible, competent in creating different shapes and sizes, and finds application in businesses such as bundling, car contributions, and buyer merchandise fabricating for its effectiveness and flexibility.

Conclusion

In conclusion, the assortment of casting and molding machines highlighted illustrates their vital part in advanced mechanical operations. Each sort caters to particular fabric necessities and generation scales, whether for high-volume plastic generation or complicated metal component fabricating. By tackling these advances, businesses can accomplish not as it were effectiveness and accuracy but moreover versatility in the assembly of assorted advertise requests over divisions like car, bundling, and aviation.