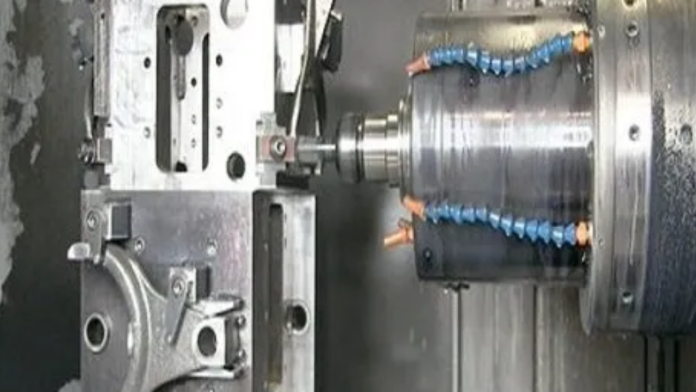

Numerous improvements in manufacturing processes have been made over time. CNC machining and milling is one of the products of the Fourth Industrial Revolution. Computer Numerical Control is referred to as CNC. Computer numerical control machining (CNC) is a precision manufacturing technique that uses computer software that has been core-programmed.

CNC machining is particularly beneficial to the manufacturing sector. When compared to manual machining, computer numerical control (CNC) technology increases productivity, accuracy, and safety while lowering costs. In terms of manufacturing precision, efficiency, and versatility, CNC machining and milling are unmatched. Numerous advantages of cnc machining and milling in a range of manufacturing processes.

Perks of CNC Milling and CNC Machining

Numerous benefits are provided by CNC (Computer Numerical Control) machining and CNC milling in a range of manufacturing processes. The following are some of the main benefits:

Quality and Consistency:

Unmatched precision and accuracy are two of the main benefits of CNC machining and CNC milling. Tight tolerances and complex designs are possible with computer-controlled systems, guaranteeing that every part fulfills precise requirements. This degree of accuracy is essential in sectors like aerospace, medicine, and automotive, where even the smallest deviation can cause problems with performance or result in a defective product.

Enhanced Efficiency:

Compared to conventional techniques, CNC machining and milling processes are much more efficient, resulting in much shorter production times. Automation makes it possible to work continuously with little downtime in between tasks. Production workflows are streamlined and overall efficiency is raised through the ability to program and automate workpiece repositioning, tool changes, and other procedures.

Reproducibility and Reliability:

CNC technologies are excellent at producing results that are both repeatable and consistent. Manufacturing consistency is a key component of quality. Once a program is flawless, there is no chance of human error during its endless replication. This contributes to a dependable and standardized manufacturing process by guaranteeing that every product meets the same high standards, regardless of the production volume.

Complex Geometries:

The use of CNC machining and milling makes it possible to produce extremely complex geometries that would be difficult or impossible to accomplish using conventional techniques. Creating complex shapes, contours, and interior features is made possible by the ability to precisely control the movement of cutting tools on multiple axes. This ability is especially useful in fields where complex and personalized designs are commonplace.

Versatility in Actual Selection:

CNC machining and milling are not bound to specific materials; they can be activated to an avant-garde ambit of materials, including metals, plastics, composites, and avant-garde abstracts like titanium and ceramics. This versatility makes CNC technologies acceptable for assorted industries with assorted actual requirements, allowing manufacturers the adaptability to acclimate to changing bazaar demands.

Waste Reduction:

Precision ascendancy and able toolpaths in CNC machining abbreviate actual waste, accidental to an added acceptable accomplishment process. The adeptness to optimize acid paths and aerate actual acceptance ensures that raw abstracts are acclimated efficiently, abbreviating both costs and ecological impact. This is abnormally important in today’s environmentally acquainted accomplishment landscape.

Enhanced Safety:

By reducing direct human involvement in the machining operation, CNC machining and milling processes improve workplace safety. Operators are exposed to fewer risks when automated systems are in place, creating a safer work environment. Furthermore, cutting-edge safety features like collision detection reduce risks even more, safeguarding workers and pricey equipment.

Cost-Effectiveness:

Although CNC equipment and software can require a sizable initial investment, these technologies are unquestionably cost-effective in the long run. Over time, the production costs per unit are lowered as a result of improved productivity, decreased material waste, and decreased human error. Furthermore, without incurring large retooling expenses, manufacturers can adjust to changing market demands thanks to the versatility of CNC machines.

Conclusion

Standing as essential cornerstones, CNC machining, and CNC milling provide unmatched accuracy, effectiveness, and adaptability. These technologies shape industries, ensuring consistent quality, decreased waste, and a path toward a more innovative and sustainable future. They do this by enabling complex designs and cost-effective production.